It’s very easy to be wasteful, particularly when you have an abundance of resources. However, as we all know, natural resources are far from that in the modern world we live in – in fact, our reserves are fast running out.

If you paid much attention to the events of the recent COP26, which took place in Glasgow at the beginning of November 2021, you’d know all too well about the commitments made globally by both political and business leaders to assist in the fight against climate change.

While news of our need to stop our rampaging damage to the environment is certainly not ‘new hat’, a concept which is ‒ and which has gained prominence and popularity in recent times ‒ is that of a ‘closed loop’.

So, what is a closed loop?

Businesses and entire sectors are attempting and investing in the implementation of a closed loop supply chain – which involves the traditional supply chain as we know it (forward logistics) being combined with reverse logistics. Ultimately, the system looks into what happens to items and materials once they’ve served their initial, intended purpose.

Effectively, once items have been manufactured, shipped, and distributed, a plan begins to return the item once it’s no longer needed or usable. Once returned, it can be repaired, resold, or simply broken down into the original materials for further use in alternative products. The closed loop aspect refers to the fact that the value from the creation of the product is never lost nor escapes from the supply chain. Instead it is utilised and reused to the best of its ability, reducing waste and improving sustainability.

It sounds pretty simple, doesn’t it?

Why does the defence sector require attention?

A closed loop, or at least further attempts to reduce the gap, would currently be idealistic rather than realistic for the defence sector – and here’s the reasons why.

Did you know that the estimated greenhouse gas emissions for the military industrial sector using a production-based approach in the financial year 2018-2018 was approximately 6.5 million tonnes of C02 equivalent (tCO2e)? This figure is greater than the total emissions of more than 60 nations worldwide.

In 2018, meanwhile, the greenhouse gas emissions of UK military spending (using the same production-based approach) is estimated at a whopping 11 million tCO2e. Using the same comparison as before, this number is equal to the total CO2 emitted by the annual average milage driven by 6 million cars.

Furthermore, the above estimates do not include the emissions produced during weapon use on the battlefield.

With plans to significantly increase military spend, increase activity, deploy high energy consuming vehicles, and expand overseas military bases, the likelihood of the defence supply chain being able to drive down emissions in the near future seems rather unlikely.

Similarly, any future decision to mount military operations could have detrimental impacts on any achievements that have been made in the area of greenhouse gas emission reduction.

A closer look at defence’s output

A report by Scientists for Global Responsibility, written by Stuart Parkinson (2020), declared that the emissions for the top 25 companies which supply the defence sector sits at around 900,000 tCO2e.

In terms of indirect employment, the report estimates that companies which provide goods and services to the UK arms industry and other major military supplies including components and raw materials account for 1.16 million tonne CO2e. To add to this, using the same theory, they’ve calculated that emissions associated with arms exports would be approximately 0.5 million tonnes of CO2e.

What does this tell us?

Well, the first major thing to note is the fact suppliers to the defence industry have an important role to play in making their own supply chain and process more sustainable but, similarly, to assist the entire sector in helping to drive down its emissions.

The Defence Standard 00-051 was published back in 2018 and it helps ensure that contractors are operating sustainable systems for managing environmental requirements. Similarly, the Government Code of Conduct, which the MOD contributes to, lays out a list of standards and behaviours expected from suppliers fulfilling MOD contracts.

Perhaps the most important thing to note from the statistics above, however, is the sheer amount of work the sector has to do in order to make progress towards achieving a sustainable future.

How do things currently look?

Sustainable methods are being employed across the sector. The replacement of General Service Canvas Tents for example has proved to be a particularly successful decision. Replacing canvas with PVC has not only created stronger tents which last longer, but they’re also more easily repaired in field, more cost-effective, and reduce the need for artificial light thanks to a white interior which helps light disperse throughout.

Likewise, the MOD is working hard to considerably reduce its paper usage through effective management and a change in behaviour. Schemes such as ‘paper free February’ and ‘think before you print’ have proved successful.

These are just two examples of ways in which the defence sector has attempted to drive down waste. However, it is the stage beyond this which ensures that a closed loop will be achieved. Rather than simply swapping out canvas for PVC, the sector needs to ensure that the PVC tents, once no longer useful to the military, are returned successfully to the manufacturer to be repaired, completely restructured and reimagined, or broken down so the materials that they were initially developed with can be utilised in the development of another product.

Of course, for the defence sector, due to the nature of many of their operations, achieving something like this may prove difficult – but a closed loop doesn’t need to start with weaponry and equipment from the battlefield. Instead, the sector could start with the domestic products that have simply passed their usable life but, have previously been discarded rather than appropriately recycled.

For this to work will take considerable thought, effort and ingenuity together with a change of mindset. The onus must be shared between defence buyers and suppliers, as without full cooperation, it’ll be simply impossible to implement.

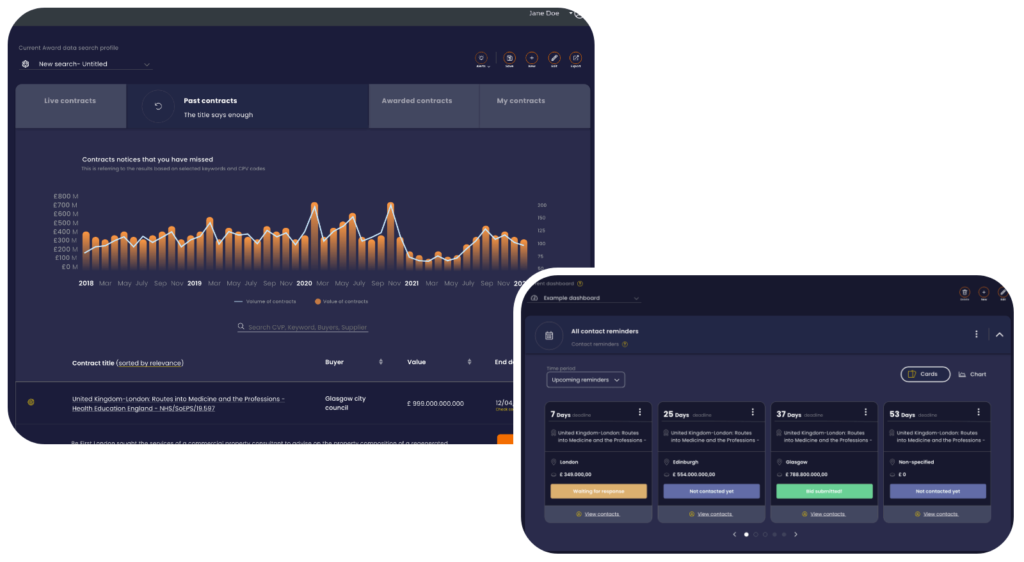

If you think your business could cater to one of the defence sectors thousands of contracts and want to find out more about the wide variety of defence contracts available online today, why not request a demo? Who knows, you could help close the loop thanks to your services.